Considerations While Choosing Coil Winder Machine

You will have to spend the requisite time if you need to choose the right coil winder machine. The selection process also depends on the final operation requirements that you have. Basically, as a buyer, you should know exactly what you are expecting from the coil winding machine in terms of the final output, compatibility with other machines, application environment, etc.

-

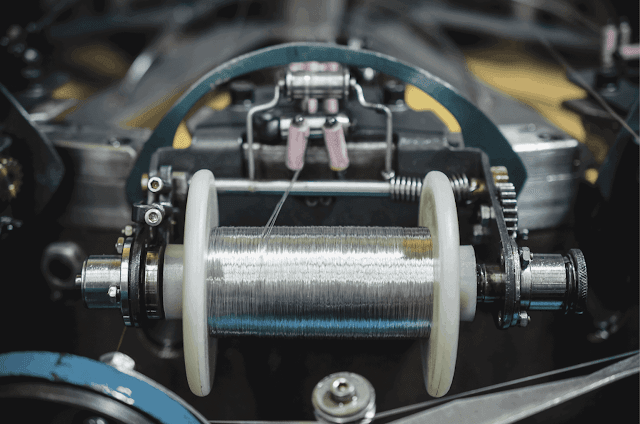

It is essential

to take one thing into consideration, i.e., the physical design of the coil.

The physical design includes several aspects: the weight of the coil, wire

diameter, coil dimension, and plenty more.

-

The next thing to

consider is the coil winding method. For this, you need to pay attention to

certain things like. Will the coil be wound at slow speeds with high torque or

high speeds with low torque? What method you want to employ to wind the coils

needs to be taken into consideration if you're going to ensure choosing the

right machine.

-

You can also keep

the rate of production in mind to check before purchasing. If you are unsure

how to choose the suitable machine for your requirements, you can get the

professional assistance that leading coil or transformer winding

machine manufacturers offer.

- You need to make sure you get such machine solutions ensuring durability and cutting-edge production capabilities. This way, you can make the right decision and choose the best solution for both efficiency and quality.

You can contact George Stevens Manufacturing. Having a growing global customer base, they offer both custom and standard solutions for any transformer winding and coil winding application. From hand-fed bobbin winders to Guitar Pickup Winder to microprocessor-based systems for automating coil winding functions, their full line of solutions and replacement parts guarantee streamlined, long-lasting production and top-notch performance.

For more

information, visit - Geostevens.com

.png)

Comments

Post a Comment